Due to the ability of a wind farm to generate enough energy to replace other sources of power, wind energy has gained traction as one of the world’s most desired renewable energy sources. In 2020, wind accounted for 17GW of new renewable energy generation in the U.S., according to the U.S. Department of Energy, and the largest increase globally in 2021 at 17%.

In order to continue to build out this renewable resource for decades to come, it will be important for people and our policymakers to understand the foundation of wind development to ensure we don’t bottleneck the development because of the lack of understanding of what actually comprises the full supply chain. In recent months, lawmakers, at the request of their voters have shut down vital mines, pipelines, and oil and gas development necessary for the build-out of wind energy.

So, what does building a wind farm entail?

Iron Ore

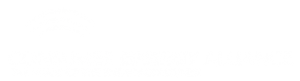

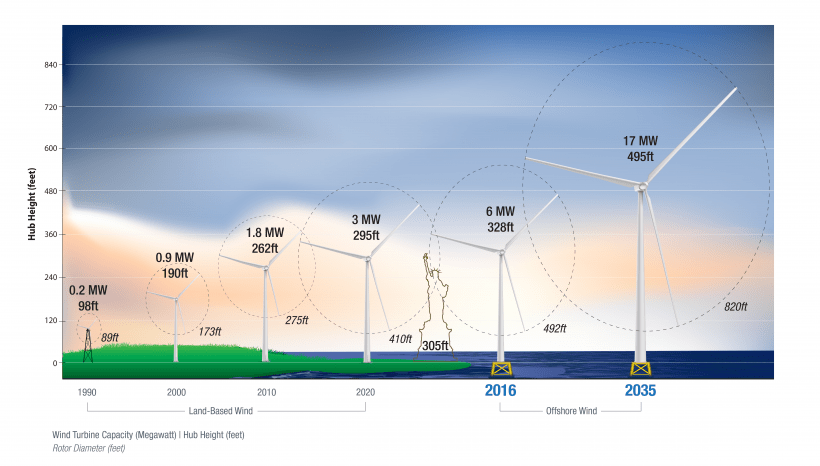

Among the many different minerals used to create a wind turbine, iron is incorporated throughout the entire turbine. From the rotor to its nuts and bolts, iron and steel make up iron and steel make up an average of 80% of all wind turbines. How much iron and steel depends on the turbine tower since they come in varying heights and types. However, the most utilized style is a tubular steel tower that incorporates a substantial amount of iron and steel compared to the others. Towers also vary in size. Onshore windmills are on average 295 feet – about as tall as The Statue of Liberty. While offshore wind towers are between 328 to 495 feet – almost as tall as the Washington Monument. The number of windmills in each farm varies by size, but to replace existing energy produced by other sources, windmills have gotten larger and so have the number of turbines on each farm. That means more iron will be need to be mined to support wind development in the United States since 60-75% of the materials for wind towers are domestically sourced.

Concrete

Newer technology for wind energy is emerging each year, and one of the materials necessary to accommodate these advances is concrete. In order to build taller wind turbines with longer blades, a heavy-duty concrete foundation is needed to stabilize and ensure the structures can withstand time and wind pressure. Often that means these foundations are 10-20 feet thick and 60 feet in diameter – or 2,827 square feet – larger than the average single-family home. Making concrete is a very heavy carbon-intensive process and its removal is not currently part of the recycling and remediation process after a wind farm’s retirement. While concrete allows the construction process to be efficient in both cost and time it is a major factor in the development of windmills, which means the use of small and large rocks. Concrete starts to break down in as little as 50 years, but according to Science.org, concrete from the Roman Empire is still standing so recycling will be the next big undertaking for the industry.

Plastic

Although it may seem counterintuitive, plastic is necessary to create this renewable resource. Lightweight plastic composites are used to design durable and aerodynamic blades that continue to evolve into lighter, long-lasting designs. In 2020, the U.S Department of Energy noted that 91% of newly installed turbines were 410 feet – or longer than a football field. Recent trends in wind farm construction are incorporating taller towers and longer blades to capture more wind. The taller the tower, the longer the blades the more composite will be needed, and more than 50 tons of plastic are contained in the blades of a 5 MW wind turbine. What binds the fiberglass into a composite is epoxy resin, a chemical substance whose base is reliant on benzene and propylene – aggregates of natural gas liquids developed through the refining of oil and natural gas.

These composites are also used in the nacelles of the wind turbine, which houses the engine.

In order to meet the mandates set by lawmakers across the country, all of these materials (not including copper or aluminum) are needed to sustain each individual piece of the wind tower. As we progress in creating a diverse energy mix by incorporating and increasing the number of renewable energy sources, it is important to know and understand each of the pieces and parts so we don’t intentionally make it harder to develop these resources, which were down 25% in 2021 due to bottlenecks, opposition and permitting issues.