As the United States and the world look for ways to decarbonize, there is one thing for sure: there is no silver bullet. There are many ways for people, businesses, and governments to look at ways to decarbonize. For people, it could be through their buying power and dictating to the market what is essential to them by, say, not buying a product that is heavily carbon-intensive to produce. For businesses, maybe it is through new technology, and for government, it might be through new regulations.

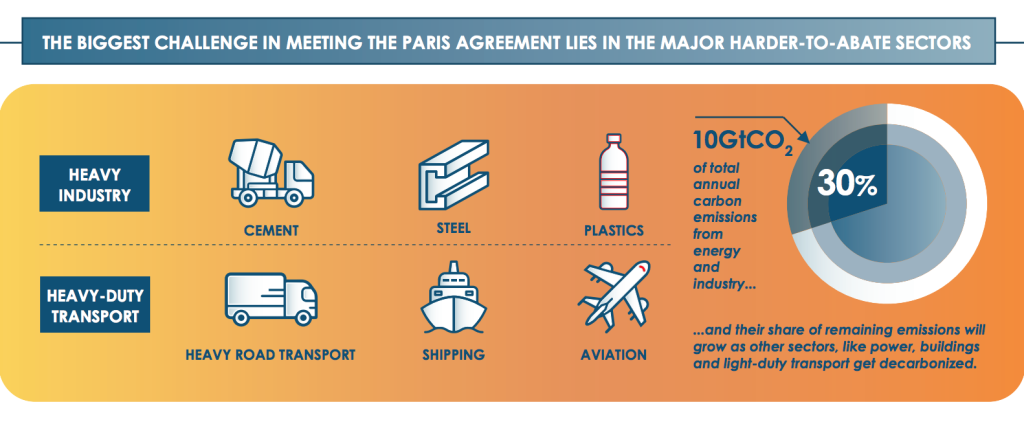

Regardless, there is not a one-size-fits-all approach. One thing is for sure. No matter what people, businesses, or governments do, there are still energy-intensive, hard-to-decarbonize sectors that everyone relies on to maintain our cities and their infrastructure and transport people and products worldwide. These sectors are the backbone of the American economy: steel, glass, chemical, fertilizer, power, cement, and iron producers, along with transportation like aircraft, maritime shipping, and truck freight. They help us build and power our homes and cities, produce and transport the food and products we use every day, and employ and transport millions of people across the U.S. Yet, these processes require very high heat and specific fuel to operate and meet product safety requirements, which means they need traditional fuels.

They also represent 20% of the CO2 emissions in the U.S. and almost 40% worldwide as the need for industrial products grows with the increasing population and socioeconomic changes. Whether it’s Brookings, the U.S. Department of Energy, or the Environmental Defense Fund, each agrees that cutting emissions from these sectors will require carbon capture and storage (CCS) and possibly even some utilization—the U in CCUS—if we’re going to make progress on our emissions goals. Not because it is THE solution, but because it is A solution. And we’ll need many.

What’s the difference between CCS and CCUS?

Carbon Capture and Storage (CCS), or carbon sequestration, involves capturing carbon dioxide (CO2) from industrial processes and transporting it through a pipeline to an appropriate geological formation for safe, permanent storage underground. Think of it as a waste management business.

Carbon Capture Utilization and Storage (CCUS) is a process and technology that helps reduce carbon dioxide (CO2) emissions from the atmosphere while continuing to meet present and future energy demands. It involves the following steps:

- Capturing CO2 from industrial sources such as coal and gas power plants or cement and steel plants, to name a few.

- Transporting the compressed CO2 to a dedicated geological storage site to use later as a gas or fluid in enhanced oil recovery (EOR) or to make other products.

- Using the CO2 in EOR or injecting compressed CO2 into a deep subsurface rock formation where it will remain permanently for geological sequestration.

However, CCS and CCUS aren’t new; in fact, the first large-scale CO2 injection project, which took place in the Sharon Ridge oilfield in Texas in 1972, ran both CCS and CCUS operations.

Capturing Emissions at the Source

Based on where you live in the country, you might be closer to areas that have large, stationary industrial facilities. These facilities are likely some of the hard-to-decarbonize industrial processes listed above. They also likely employ people in your state, if not your community, generate income that leads to a healthy economy, and provide social well-being and a sense of community. Despite these positive attributes, CO2 emissions can lead to detrimental health effects. While some national activists team up with community members to express their desire to shut a facility down, they often forget that closing down a plant or facility is hard. This is because moving or closing an existing industrial facility can be challenging and expensive, and often, there isn’t a big enough business to replace it—leading to hardships for the people and community it is in. It’s also inadvertently costly to consumers, the local economy, and the larger supply chain.

However, adding CCS or CCUS technology to these facilities helps maintain those jobs, the needed products they produce, and revenue while reducing harmful emissions. This is a win-win for the community and the people.

How Does CO2 Get Captured and Where Does it Go?

Outside of nature, like forests, coastal wetlands, and restorative agricultural processes, CO2 gets captured in many different ways, including pre-, post-, or oxy-fuel combustion, absorption, or direct air capture (DAC). While DAC is still in its early stages, the most common type of capture is through chemical combustion, converting or separating molecules. Once converted or separated, these molecules are captured as a gas and pressurized into a liquid, where a pipeline transports it to a suitable geological storage site chosen for its specific geological properties. These sites are either depleted oil and gas fields, deep saline geologic formations (or salt domes), utilized in the EOR process, or in coal seams—though that is rare.

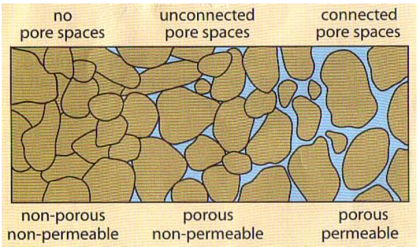

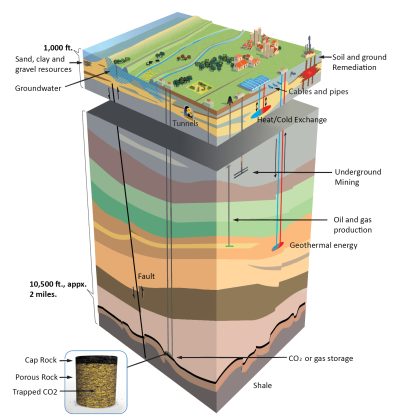

Once a site is selected, the CO2 is injected deep into the Earth’s surface, well below fresh water sources into the rock formation. How much CO2 can be deposited depends on how much “pore space” there is to trap it. Pore space is the empty spaces between sand and rock, similar to the spaces in a sponge when it collects water. Unlike water, CO2 is buoyant. However, there is a layer of earth called caprock that lies above these porous areas, and they are water-tight, trapping the CO2 and preventing it from rising. From there, companies install monitoring equipment to keep track of the safety of the well.

How Deep are these Storage Sites?

The depth of these geologic storage sites varies depending on the local geology. At a minimum, the site has to be over half a mile below the surface, with some sites almost 2 miles deep. Geologists look closely at the formations to determine where the water table is to determine how far down a well will need to be drilled.

Once trapped, over hundreds or thousands of years, the CO2 undergoes a chemical reaction—or mineralization—with the rock in that formation and forms a carbonate. Carbonates can form from minerals like calcium or magnesium to become calcite (an element of limestone), magnesite (made through the alteration of limestone or marble), or dolomite (used instead of limestone). All to say, though it is a long process, there are rock-solid results!

What are the Best Areas for Carbon Storage?

This can be answered in two ways. First, as we discussed before, the best places for carbon storage are either depleted oil and gas fields, deep saline geologic formations (or salt domes), utilized in the EOR process, or in coal seams—though that is rare.

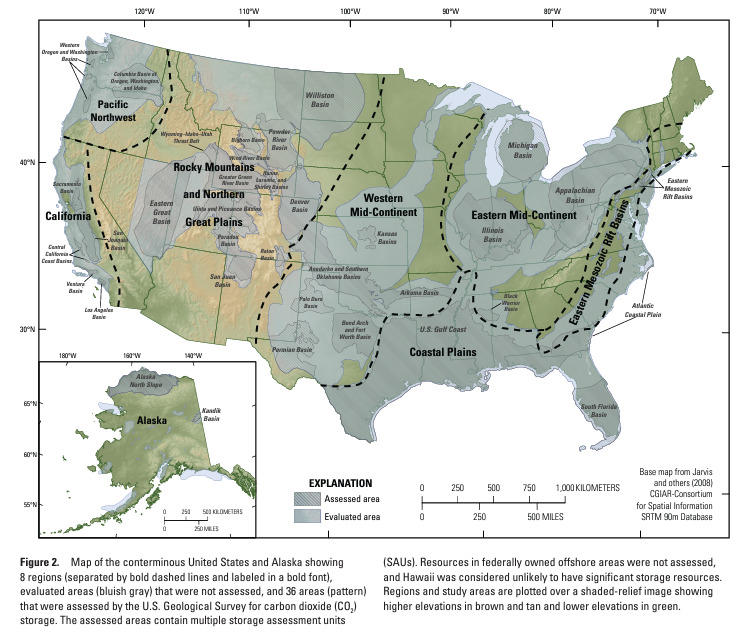

Second, if you’re thinking of regionally where those places are, the U.S. Geological Service says “the best” area for carbon storage is really subjective. However, they do address storage potential or technically accessible storage based on the amount of CO2 a region can store underground. That said, they identify the Coastal Plains from Texas to Georgia as capable of holding 65% of our country’s “storage potential.”

Geologists prefer this area as much of the storage can occur in the salt domes, which are far below the surface. The pressure in these formations helps keep the CO2 in place at a solid state, where it has less of a chance to leak.

Alaska and the Rocky Mountains/Northern Great Plains have the next most significant storage potential. These regions tend to be where some of the most productive oil and gas fields are located.