Louisiana’s industrial sector is part of the backbone of the American economy. Everything from steel, glass, chemical, fertilizer, power, cement, and iron producers to the transportation sector with aircraft, maritime shipping, and truck freight. Louisiana helps power homes and businesses and provides needed feedstocks and components for thousands of everyday products. We also produce and transport the food and goods we use every day. The infrastructure and the industry have been long established and are something our locals take pride in. However, these industrial processes require very high heat and specific fuel to operate and meet safety requirements, which means they need traditional fuels.

As of 2019, Louisiana has the seventh highest CO2 emissions in the nation, with roughly 60 percent of emissions coming from the industrial sector and 14 percent from power generation, according to the Regional Carbon Capture Deployment Initiative. Whether it’s Brookings or the U.S. Department of Energy—under both Democratic and Republican Administrations – cutting emissions from these sectors will require carbon capture and storage (CCS) and possibly even some utilization—the U in CCUS—if we’re going to make progress on our state’s emissions goals and help maintain the industries and jobs Louisianans rely on.

How Does Capturing Carbon Help Louisiana Increase Jobs, Investments, and Other Economic Benefits?

Economic studies have shown that developing a carbon capture and storage industry in Louisiana could add 2,700-4,000 permanent jobs annually over the next 15 years, with some paying between $80,000 -$90,000 per year. There could also be an additional 1,700 to 2,500 jobs a year to retrofit and operate existing CCS infrastructure. A good example is a project in Calcasieu Parish that could create 970 jobs alone.

These industrial jobs also provide an influx of property tax revenue to local governments and enable new community partnerships—whether it be support for early childhood centers, workforce development for high school students, or funding for county roads and bridges.

CCUS has also garnered support from large and small independent manufacturers and energy producers because it represents a real opportunity for new high-paying jobs in the industrial and manufacturing sectors. Reducing the carbon footprint of these facilities is vital to ensuring they can operate and keep providing jobs for many more years—no matter who is in charge at the White House.

Capturing Emissions at the Source

In the United States, 60% of the electricity generated in 2023 came from traditional fuels like coal, natural gas, petroleum, and others. In Louisiana, that number increases to 76% as natural gas is the state’s leading fuel source for electric generation. The Energy Information Administration also notes that natural gas fuels 6 of Louisiana’s 10 largest power plants. The state also has the nation’s highest residential sector per capita electricity consumption, with roughly 7 in 10 state households relying on electricity for home heating, and almost all households have air conditioning. These figures alone highlight how Louisiana could lead a new carbon economy.

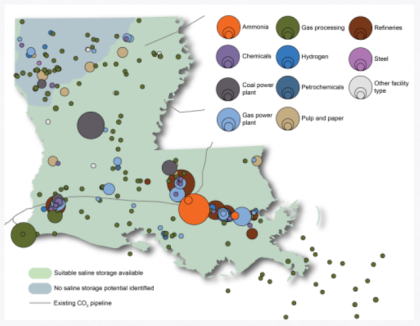

Based on where you live in Louisiana, you might be closer to areas that have large, stationary industrial facilities. Currently, roughly 61 facilities have been identified as candidates for carbon capture retrofit, according to the Regional Carbon Capture Deployment Initiative. These facilities are likely some of the hard-to-decarbonize industrial processes listed above. They also likely employ people in your Parish, if not your community, who generate income that leads to a healthy economy and provides social well-being and a sense of community. While some national activists team up with community members to express their desire to shut a facility down, they often forget that closing down a plant or facility is hard. This is because moving or closing an existing industrial facility can be challenging and expensive, and often, there isn’t a big enough business to replace it—leading to hardships for the people and community it is in. It’s also inadvertently costly to consumers, the local economy, and the larger supply chain.

Adding CCS or CCUS technology to these facilities helps maintain high-paying industrial and manufacturing sector jobs, the needed products they produce—not to mention the affordability of those products—and revenue the facilities generate for the community and the state, all while making the air around these facilities cleaner to breathe. This is a win-win for the community and the people.

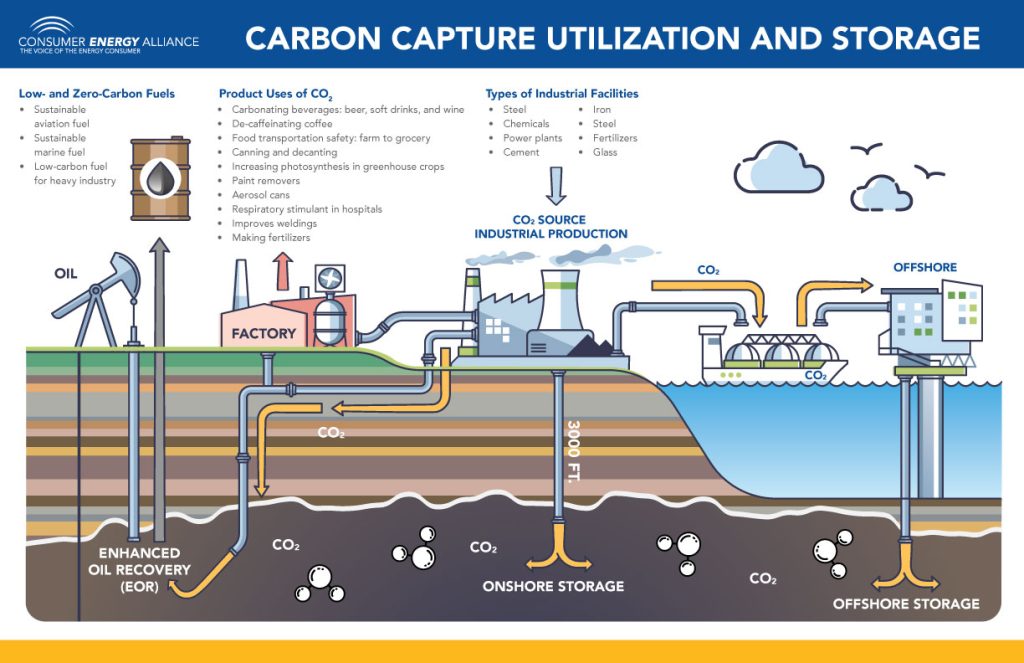

How Does CO2 Get Captured and Where Does it Go?

Outside of nature, like forests, coastal wetlands, and restorative agricultural processes, CO2 gets captured in many different ways, including pre-, post-, or oxy-fuel combustion, absorption, or direct air capture (DAC). While DAC is still in its early stages, the most common type of capture is through chemical combustion, converting or separating molecules. Once converted or separated, these molecules are captured as a gas and pressurized into a liquid, where a pipeline transports it to a suitable geological storage site chosen for its specific geological properties. These sites are either depleted oil and gas fields, deep geologic formations, or utilized in the EOR process.

Once a site is selected, the CO2 is injected deep into the Earth’s surface, far below fresh water sources, into a specified rock formation. How much CO2 can be deposited depends on how much “pore space” there is to trap it. Pore space is the empty spaces between sand and rock, similar to the spaces in a sponge when it collects water. Unlike water, CO2 is buoyant; however, there is a layer of earth called caprock above these porous areas, and they are watertight, trapping the CO2 and preventing it from rising. From there, companies install monitoring equipment to keep track of the safety of the well.

How Deep are these Storage Sites?

The depth of these geologic storage sites varies depending on the local geology. At a minimum, the site has to be over half a mile below the surface, with some sites almost 2 miles deep. Geologists look closely at the formations to determine where the water table is to determine how far down a well will need to be drilled.

Once trapped, over hundreds or thousands of years, the CO2 undergoes a chemical reaction with the rock its been injected into – changing from a gas to rock. Though it is a long process, there are rock-solid results!

What are the Best Areas for Carbon Storage?

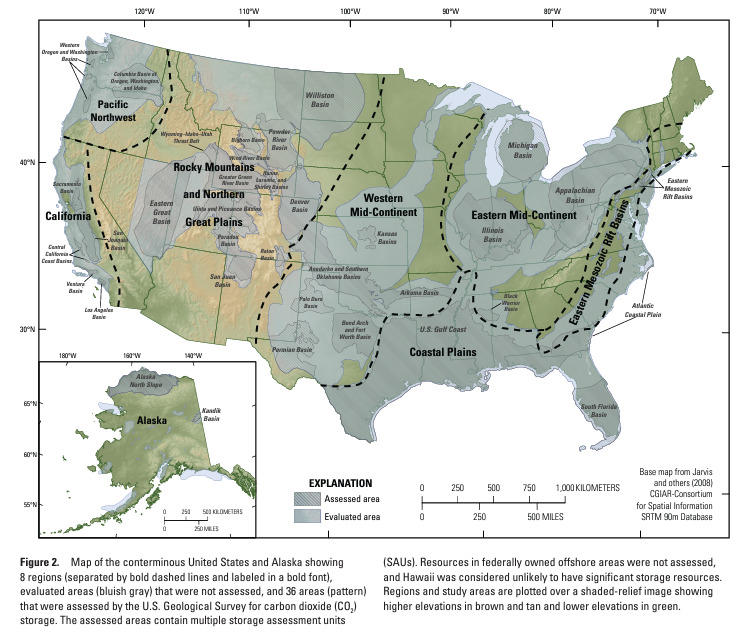

This can be answered in two ways. First, as we discussed before, the best places for carbon storage are either depleted oil and gas fields, deep geologic formations utilized in the EOR process, or in coal seams—though that is rare.

Second, if you’re thinking about where those places are regionally, the U.S. Geological Service addresses storage potential or technically accessible storage based on the amount of CO2 a region can store underground. That said, they identify the Coastal Plains from Texas to Georgia as capable of holding 65% of our country’s “storage potential.” This is why there has been so much conversation about CCS in Louisiana and why the state has worked hard to secure its own primacy. At some point, Louisiana could be the epicenter and leading expert in carbon storage.